CNC Precision Machining in China: How to Choose?

Selecting the right CNC precision machining service provider in China is crucial for achieving high-quality, accurate, and cost-effective machined parts. To make an informed decision, several factors need to be considered. Below are the detailed steps to guide you in choosing the right CNC precision machining service in China.

Research and Evaluation

Supplier Identification

Start by identifying potential CNC precision machining suppliers in China through online research, industry directories, and referrals from business associates.

Company Background Check

Conduct a thorough background check on each potential supplier, reviewing their experience, capabilities, certifications, and customer reviews.

Capability Assessment

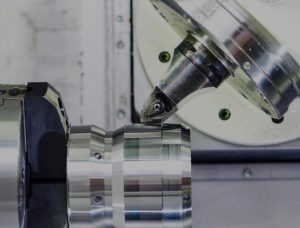

Machining Equipment

Evaluate the machining equipment and technology used by each supplier, ensuring they have state-of-the-art CNC machines capable of handling your project requirements.

Material Expertise

Assess the supplier’s expertise in machining various materials, including metals, plastics, and composites, ensuring they can work with the materials required for your project.

Quality Assurance Processes

Quality Certifications

Verify that the supplier holds relevant quality certifications such as ISO 9001, indicating their commitment to maintaining high-quality standards.

Inspection Procedures

Inquire about the supplier’s inspection procedures and quality control measures, ensuring they conduct thorough inspections at every stage of the machining process.

Communication and Collaboration

Communication Channels

Establish clear and effective communication channels with potential suppliers, ensuring there is open dialogue to discuss project requirements, specifications, and expectations.

Collaboration Approach

Look for a supplier willing to collaborate closely throughout the machining process, providing updates, addressing concerns, and accommodating any necessary changes.

Cost Considerations

Quotation Comparison

Request detailed quotations from multiple suppliers, comparing factors such as unit price, tooling costs, setup fees, and additional charges.

Value for Money

Evaluate the overall value proposition offered by each supplier, considering factors such as quality, lead times, customer service, and post-sales support.

Delivery and Lead Times

Production Capacity

Ensure that the supplier has the production capacity to meet your project’s volume requirements within the desired timeframe.

Lead Time Commitment

Discuss lead times and production schedules with potential suppliers, ensuring they can deliver the machined parts according to your timeline.

Conclusion

Choosing the right CNC precision machining service provider in China requires thorough research, evaluation of capabilities, assessment of quality assurance processes, effective communication, consideration of cost factors, and attention to delivery schedules. By following these steps and partnering with a reputable CNC precision machining supplier, you can ensure the successful execution of your machining projects. For top-quality CNC Precision Machining in China, visit CNC Precision Machining China today.